Iingcingo ezahlukeneyo zokujija i-coil, iingcingo ezimbini, iingcingo ezininzi, inxeba lekhekhe elikhethekileyo, i-enamelled wire, iinkcukacha ezahlukeneyo ezenziwe ngokwezifiso.

Ingcaciso yeMveliso

1. Iimpawu:Iinkcazo ezenziwe ngokwezifiso kunye neentlobo ze-insulation layer, kunye nomgangatho ongaphezulu unokugqunywa ngomqolo wokuzincamathela.

2. Uluhlu lweenkcazo:umgca omnye kunye neenkcukacha ezifanayo kodwa imibala eyahlukileyo, iinkcukacha ezahlukeneyo kunye neentlobo ezahlukeneyo (uluhlu lwenkcazo yomgca omnye: 0.03mm-0.500mm).

3. Ukusetyenziswa kwemveliso:Isetyenziswa ikakhulu kwiimveliso zenxeba eziphindwe kabini/ezininzi zocingo olunxuseneyo, ezinje ngee-inductors ezikhethekileyo, ii-RF transformers, njl. Inokuthi ifakwe kwiindawo ezimbini / ezintathu / ezintlanu zekhoyili ezinemibala eyahlukeneyo kunye nokumelana ngokupheleleyo / ukunyanzeliswa kunye nezinye iiparameters, okanye kwiindawo ezimbini / ezintathu / ezintlanu zekhoyili ezinengcaciso eyahlukileyo kodwa ubude bocingo olufanayo.

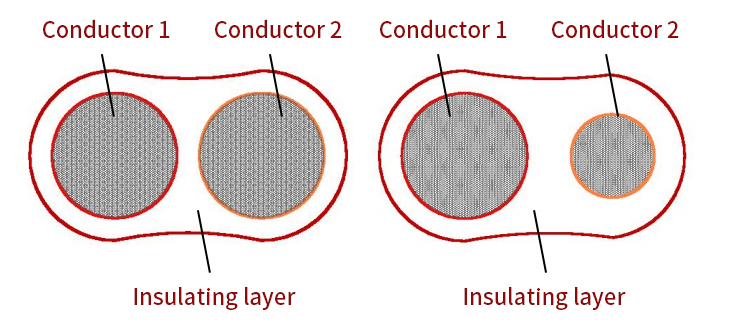

4. Umzobo weskim ngolu hlobo lulandelayo:

Inkqubo yokuhamba kocingo lwe-enamelled

1, Ukuhlawula:Kumatshini osebenza nge-enamelled ngokuqhelekileyo, amandla amaninzi omqhubi kunye namandla omzimba asetyenziswa kwinxalenye yokuhlawula. Ukutshintsha i-reel yokuhlawula kwenza ukuba umqhubi ahlawule umsebenzi omninzi. Iingxaki zomgangatho kunye nokungaphumeleli kokusebenza kulula ukwenzeka kumgca wokudibanisa umgca. Indlela esebenzayo kukuhlawula umthamo omkhulu. Undoqo wokuhlawula kukulawula uxinzelelo. Xa ukuxhatshazwa kukhulu, akuyi kunciphisa kuphela umqhubi, wenze ubuso bomqhubi ulahlekelwe ukukhanya, kodwa kuchaphazela iipropati ezininzi zocingo lwe-enamelled.

2. Ukolula:Injongo yokwelula kukwenza umqhubi owenziwe lukhuni ngenxa yokutshintsha kwe-lattice ngexesha lenkqubo yokwelula i-mold evuthayo kwiqondo lokushisa elithile, ukwenzela ukuba ukuguquguquka okufunekayo yinkqubo kunokubuyiselwa emva kokuhlengahlengiswa kwe-lattice ye-molecular. Ngelo xesha, i-lubricant eseleyo kunye ne-oyile ye-oyile kwi-conductor surface ngexesha lenkqubo yokwelula ingasuswa, ukwenzela ukuba umqhubi unokupeyintwa lula kwaye umgangatho wocingo lwe-enamelled unokuqinisekiswa.

3, Ukupeyinta:ukupeyinta yinkqubo yokwaleka ipeyinti yocingo enamelled kwi conductor metal ukwenza umaleko ipeyinti iyunifomu kunye ubukhulu ethile.

4. Ukubhaka:Njengokupenda, ukubhaka yinkqubo ejikelezayo. Okokuqala, i-solvent kwisisombululo sepeyinti i-evaporated, ize iphiliswe ukwenza ifilimu, kwaye ipeyinti iyabhaka. Ukungcola kuya kuveliswa kwinkqubo yokubhaka, ngoko isithando somlilo siya kukhutshwa ngokukhawuleza. Ngokubanzi, iziko lokujikeleza komoya oshushu liya kusetyenziswa. Ngexesha elifanayo, umthamo wokukhutshwa kwenkunkuma awuyi kuba mkhulu kakhulu okanye ube mncinci kakhulu. Ngenxa yokuba ubuninzi bobushushu buya kuthathwa kwinkqubo yokukhutshwa kwenkunkuma, ngoko ukukhutshwa kwenkunkuma akuyi kuqinisekisa kuphela imveliso ekhuselekileyo kunye nomgangatho wemveliso, kodwa kungakhokelela kwixabiso elikhulu lokulahleka kobushushu.

5. Ukupholisa:Ucingo olunamelled oluphuma kwi-oven lunobushushu obuphezulu, ifilimu yepeyinti ethambileyo kunye namandla aphantsi. Ukuba ayicoliswanga ngexesha, ifilimu yepeyinti edlula kwivili lesikhokelo iya konakaliswa, eya kuchaphazela umgangatho wocingo lwe-enamelled.

6. Ukuthambisa:i-lubrication yocingo olunamelled lunobudlelwane obukhulu kunye nokuqina kokuthatha. I-lubricant esetyenziselwa i-enamelled wire iya kukwazi ukwenza ubuso be-enamelled wire slippery, ngaphandle kokulimala kwintambo, ngaphandle kokuchaphazela amandla e-reel yokuthatha kwaye ngaphandle kokuchaphazela ukusetyenziswa komsebenzisi. Ubungakanani obufanelekileyo be-oyile kukwenza ucingo olunamelled luve lutyibilika, kodwa akukho oli icacileyo inokubonwa esandleni. Ukusuka kumbono wobungakanani, i-1 g yeoli yokuthambisa inokugqunywa kumphezulu we-1 ㎡ yocingo olunamelled.

7. Ukuthatha ucingo:Injongo yokuthatha ucingo kukusongela ucingo olunamelled kwi-spool ngokuqhubekayo, ngokuqinileyo kwaye ngokulinganayo. Kuyafuneka ukuba umatshini wokuthatha uya kuqhutywa ngokuzinzileyo, ngengxolo ephantsi, uxinzelelo olufanelekileyo kunye nokucwangciswa rhoqo kweengcingo.

Emva kokwazi inkqubo yokuvelisa i-enamelled wire ngokweenkcukacha, ngaba ucinga ukuba akulula ukuvelisa ucingo lwe-enamelled oluhlangabezana neemfuno eziqhelekileyo, kuba inyathelo ngalinye lenkqubo, njengokubhaka okanye ukupeyinta, liya kuchaphazela umgangatho wocingo lwe-enamelled, kwaye kunjalo. ikwachatshazelwa yimathiriyeli ekrwada, umgangatho, okusingqongileyo, izixhobo zokuvelisa kunye nezinye izinto, ngoko umgangatho wemveliso uya kwahluka. Nangona iimpawu zomgangatho kunye neempawu zeengcingo ezahlukeneyo ze-enamelled zihluke, ngokusisiseko zineempawu ezine, ezizezi zixhobo zomatshini, iikhemikhali, iipropati zombane kunye nezixhobo zokushisa.

1.jpg)

1-300x300.jpg)

2-300x300.jpg)

-300x300.jpg)

1-300x300.jpg)