Ukusebenza okuphezulu komatshini, ukumelana nobushushu, kunye nokumelana noxinzelelo, i-F-grade yegolide enamathelayo yeTeflon, amandla amatsha ezixhobo ze-photovoltaic.

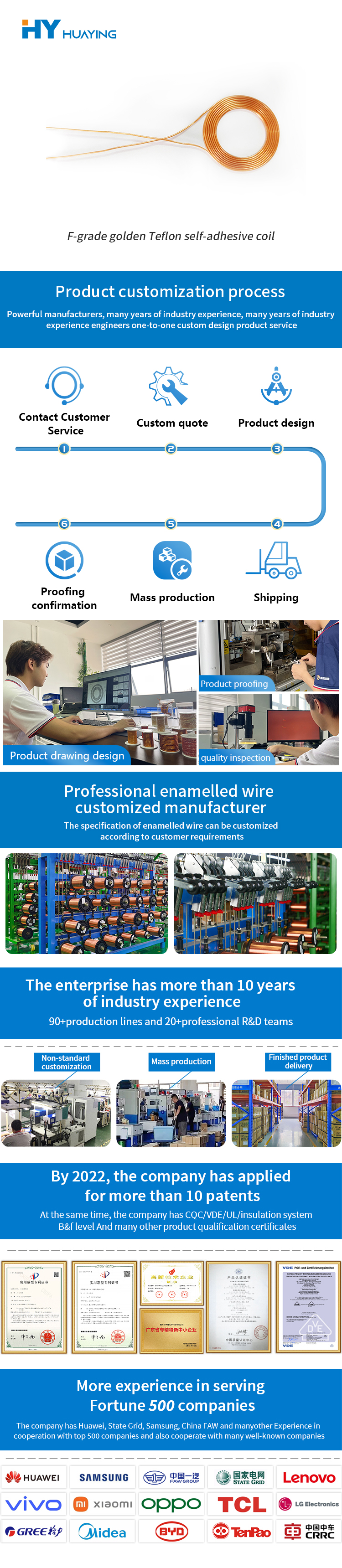

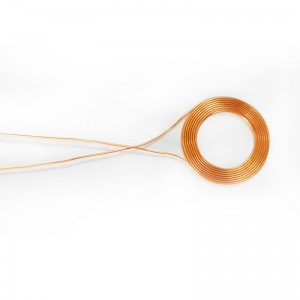

F-grade yegolide Teflon ikhoyili self-adhesive

Igama lemveliso:F-grade yegolide Teflon ikhoyili self-adhesive

I-Teflon insulated wire ibhekisela kwi-insulated wire eyenziwe nge-fluoroplastic (ETFE) njengento yokugquma. Ngenxa yokunganamatheli kwayo, ukuxhathisa ubushushu, ukuxhathisa ukutyibilika, ukuxhathisa ukufuma, ukuxhathisa ukunxiba, ukuxhathisa umhlwa, kunye nezinye iimpawu. Ke xa kuthelekiswa nezinye iingcingo ezinobushushu obuphezulu, iTeflon wire inozinzo oluhle kakhulu lwe-thermal kunye nokumelana nokunxiba komatshini, ukusebenza kombane, ukuchasana ne-acids eyomeleleyo kunye nealkali, ukubola, ukumelana nomlilo kunye nokungatsha, isalathiso seoksijini ephezulu, umsi ophantsi kunye ne-halogen-free, ukungagugi, kulula ukuxobula ucingo, ukomelela okuphezulu kunye nokumelana nokukhuhlana. Kukho umahluko othile phakathi kokumelana nokushisa kweTeflon wire kunye nempahla yezinto zokupakisha zangaphandle. Phakathi kwazo, iimpawu ze-ETFE kukusebenza kakuhle kokusebenza, iipropathi zomzimba ezilungeleleneyo, ukuqina okuhle koomatshini, kunye nokuxhathisa okugqwesileyo kwimitha. Esi sixhobo sineempawu zokuxhathisa ukubola kwe-polytetrafluoroethylene, ukoyisa ukunganamatheli kunye neziphene zesini ze-polytetrafluoroethylene kwiintsimbi. Ukongeza, i-coefficient yayo yokwandisa i-linear isondele kwi-carbon steel, okwenza i-ETFE (F-40) ibe yinto efanelekileyo edibeneyo enesinyithi.

Ukusebenza kwayo kunokumelana nokugqwesa okugqwesileyo, phantse kunganyibiliki kuyo nayiphi na i-solvent ye-organic, kwaye inokumelana neoli, i-acids eyomeleleyo, i-alkali eyomeleleyo, i-oxidants eyomeleleyo, njl. Inokusebenza okugqwesileyo kokufakelwa kombane, amandla ombane aphezulu, ilahleko ephantsi ye-frequency ephezulu, akukho kufunxa ukufuma, kunye nokuxhathisa okuphezulu kokugquma; Inokumelana nedangatye okugqwesileyo, ukumelana nokuguga, kunye nobomi benkonzo ende.

Ukulawula imilo yekhoyili:

Okokuqala, sebenzisa indlela ye-extrusion yangaphakathi ukuze ucinezele imida yekhoyili yesikwere ngaphakathi, uqinisekise ukuba ubukhulu bekhoyili buhambelana. Kodwa ingxaki ngale nto kukuba ukuba ucingo lukhutshwe emva kokulimala, ukuba ulungelelwaniso alucocekanga, luya kubangela umonakalo kwintambo kwaye lukhokelela ekuveliseni iimveliso eziphosakeleyo. Ukuba indlela yokucudisa kanye emva kokuvuthwa kolunye uluhlu lusetyenzisiweyo, isakhiwo somatshini siya kuba nzima ngakumbi kwaye iindleko ziya kuba phezulu. Ukuhambelana okuncinci.

Okwesibini, ngokusebenzisa indlela yokuphuma ngaphandle, isilonda sesetyhula okanye i-elliptical coil inokuchaneka okuphezulu kwilungiselelo locingo kunye nobukhulu obuhambelanayo kuzo zonke izikhundla. Ngokucofa i-coil yesetyhula okanye i-elliptical ukusuka kwisangqa sangaphakathi ukuya ngaphandle ngokusebenzisa isikhunta, i-coil yesikwele eveliswayo inobunzima obuhambelanayo kunye ne-conductivity kuzo zonke izikhundla. Ukungalungi kwale ndlela kukuba ayikwazi ukukhama iikhoyili ezinomaleko obuninzi okanye ubukhulu obukhulu.

Ngoko ke, xa ujija ikhoyili, ukulawulwa kobume kufuneka kuchaneke, nokuba i-angle okanye imilo, okanye ukusebenza kwentambo kuya kuchaphazeleka. Ngaphezu koko, kweyona mveliso kunye nenkqubo yokucubungula, ukusebenza ngokungafanelekanga kwimveliso yamva kunye nokucubungula kunokubangela umonakalo kwi-insulation layer, ibeka ingozi ebalulekileyo kwintsebenzo yekhoyili. Ngoko ngexesha lenkqubo yokuvelisa, imisebenzi kufuneka iqhutywe ngokungqongqo ngokuhambelana neemfuno zemveliso. Ukumiselwa kobushushu kunye noxinzelelo kufuneka kugxininiswe kumgangatho wemveliso kwaye akunakukhawuleza ngokukhawuleza.

2-300x300.jpg)